Ford Motor Company this week announced a new business plan that includes new American-made vehicles and a focused battery energy storage business. The company will no longer make large-vehicle EVs, instead developing a Universal EV Platform for smaller, affordable models.

“This is a customer-driven shift to create a stronger, more resilient and more profitable Ford,” said Ford president and CEO Jim Farley. “The operating reality has changed, and we are redeploying capital into higher-return growth opportunities: Ford Pro, our market-leading trucks and vans, hybrids and high-margin opportunities like our new battery energy storage business.”

By 2030, Ford expects approximately 50% of its global volume will be hybrids, extended-range EVs and fully electric vehicles, up from 17% in 2025. Ford will concentrate its North American electric vehicle development on its new, low-cost, flexible Universal EV Platform. This next-generation architecture is engineered to underpin a high-volume family of smaller, highly efficient and affordable EVs designed to be accessible to millions of customers. The first vehicle from the Universal EV Platform will be the fully connected midsize pickup truck assembled at Louisville (Kentucky) Assembly Plant starting in 2027.

The next-generation F-150 Lightning will shift to an extended-range electric vehicle (EREV) architecture and be assembled at the Rouge Electric Vehicle Center in Dearborn, Michigan. Production of the current generation F-150 Lightning has concluded.

“The F-150 Lightning is a groundbreaking product that demonstrated an electric pickup can still be a great F-Series,” said Doug Field, Ford’s chief EV, digital and design officer. “Our next-generation Lightning EREV is every bit as revolutionary. It keeps everything customers love — 100% electric power delivery, sub-5-second acceleration — and adds an estimated 700+ mile range and tows like a locomotive. It will be an incredibly versatile tool delivered in a capital-efficient way.”

Launching a battery energy storage system business

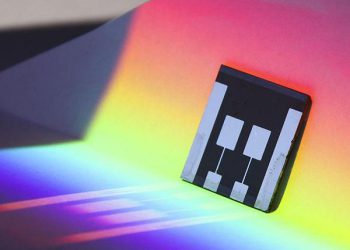

Ford is launching a new business — including sales and service — to capture the large demand for battery energy storage from data centers and infrastructure to support the electric grid. Ford plans to repurpose existing U.S. battery manufacturing capacity in Glendale, Kentucky, to serve the rapidly growing battery energy storage systems market. The company also plans to invest roughly $2 billion in the next two years to scale the business.

The Kentucky site will be converted to manufacture 5 MWh+ advanced battery energy storage systems. Ford plans to produce LFP prismatic cells, BESS modules and 20-ft DC container systems at this facility. Ford plans to bring initial capacity online within 18 months and reach at least 20 GWh annually by late 2027.

Separately, Ford will utilize BlueOval Battery Park Michigan in Marshall, Michigan, to produce smaller Amp-hour cells for use in residential energy storage solutions. This plant remains on track to begin manufacturing LFP prismatic battery cells in 2026 to power Ford’s upcoming midsize electric truck, the first model on the new Universal EV Platform.