EKO Instruments USA has launched a U.S.-based pyranometer calibration service. The service brings a new level of accuracy, cost effectiveness and turnaround speed to pyranometer calibration for utility-scale, commercial and industrial solar applications. The service will support SCADA companies, O&M teams and solar project developers, owners and operators. Correct calibration enables pyranometers to accurately fulfill their key role across the solar lifecycle, including planning stages, installation and ongoing monitoring and maintenance.

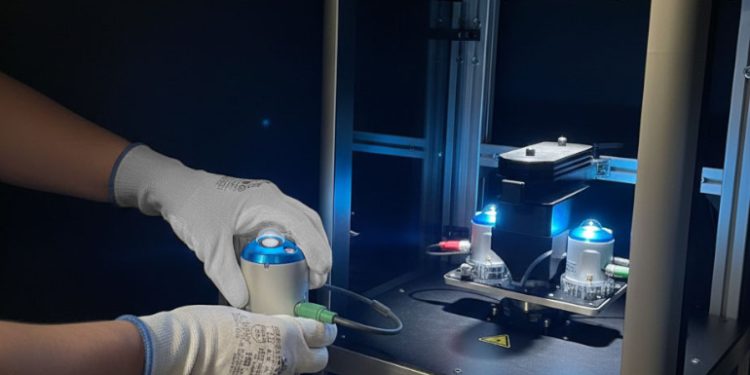

EKO’s newly developed Indoor Calibration Facility (ICF-02) calibration system forms the linchpin of the service. The Indoor Calibration Facility is a turnkey, fully automated calibration system designed to perform highly accurate and repeatable indoor calibrations of ISO 9060 spectrally flat pyranometers in full compliance with ISO 9847:2023. The facility enables direct comparison of a test pyranometer against a reference pyranometer of the same model, ensuring traceability and consistency aligned with international calibration standards.

EKO’s newly developed Indoor Calibration Facility (ICF-02) calibration system forms the linchpin of the service. The Indoor Calibration Facility is a turnkey, fully automated calibration system designed to perform highly accurate and repeatable indoor calibrations of ISO 9060 spectrally flat pyranometers in full compliance with ISO 9847:2023. The facility enables direct comparison of a test pyranometer against a reference pyranometer of the same model, ensuring traceability and consistency aligned with international calibration standards.

This new calibration service was developed to meet International Electrotechnical Commission (IEC) 61724-1:2021 calibration frequency standards.

“Amidst solar project deadlines that are tighter than ever, we’re happy to launch a faster, more cost-effective calibration service within the United States that minimizes stress for our customers while maximizing the accuracy of their solar sensors,” says Wayne Burnett, chief strategy officer and chief technology officer at EKO Instruments. “EKO’s long legacy of expertise in calibration and dedication to accuracy makes this possible.”

Conducted domestically, the U.S.-based calibration service reduces the cost of sending solar sensors to offshore laboratories, preventing logistical delays that can arise from international supply chains. EKO’s service also accelerates calibration turnaround time compared with many alternative providers, helping customers return instruments to service more quickly. The service ensures industry-leading sensitivity value – the last checkpoint metric before the solar sensor is reinstalled in the field, where accuracy of calibration is difficult to assess.

Errors from poor calibration are often subtle and even undetectable by end users, but the cumulative effect of power loss can impact the productivity and profitability of larger sites. ISO 9847:2023 solar sensor calibration involves comparing the readings of a test solar sensor against a reference solar sensor under controlled conditions. Understanding measurement uncertainties is critical in the solar sensor calibration process, whether the calibration will be done indoors or outdoors. Periodic re-calibration of solar sensors is necessary to ensure that solar energy systems can be tested and rated consistently.

“ICF-02 was designed as a scalable tool for fully automatic calibrations, enabling users to operate the system easily while achieving highly consistent and repeatable results. As adoption grows, our vision is to expand a global calibration network in close collaboration with trusted partners who operate ICF-02 facilities,” explains Kees Hoogendijk, Managing Director, EKO Technology. “This approach ensures harmonized calibration practices worldwide. Decades of hands-on experience in solar radiation measurement and calibration form the foundation of this system. That expertise is embedded in the sophisticated automation, control software and data handling of ICF-02, making reliable, traceable, and standards-compliant calibrations accessible without compromising on quality.”

News item from EKO