by Clarence Oxford

Los Angeles CA (SPX) Nov 11, 2025

Engineers at Rice University have developed a process that recovers lithium from electric vehicle battery waste using electricity and water, skipping the need for strong acids and complex chemical steps. The method applies the same reaction as conventional battery charging, driving lithium ions from spent cathodes into water where they combine with hydroxide to form high-purity lithium hydroxide.

Sibani Lisa Biswal explained, “If charging a battery pulls lithium out of a cathode, why not use that same reaction to recycle?” By employing a compact electrochemical reactor, the team separated lithium efficiently and produced the lithium salt favored by manufacturers.

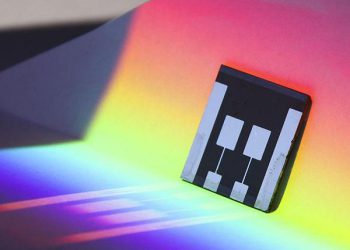

In experiments, the zero-gap membrane-electrode reactor processed industrial battery waste, achieving a recovery rate of nearly ninety percent over one thousand hours and creating lithium hydroxide with purity exceeding ninety-nine percent. The process required as little as one hundred three kilojoules of energy per kilogram of waste, far below conventional acid-leaching operations. The system scaled to twenty square centimeters and handled fifty-seven grams of industrial black mass supplied by TotalEnergies.

Haotian Wang added, “Directly producing high-purity lithium hydroxide shortens the path back into new batteries. That means fewer processing steps, lower waste and a more resilient supply chain.”

Tests showed the technology works with various battery chemistries, such as lithium iron phosphate and nickel-manganese-cobalt varieties. The researchers also demonstrated continuous roll-to-roll processing of electrodes, eliminating manual treatment.

Future goals include building larger reactor stacks, improving membrane performance, and refining postprocessing to cut energy use further.

Biswal stated, “We’ve made lithium extraction cleaner and simpler. Now we see the next bottleneck clearly. Tackle concentration, and you unlock even better sustainability.”

Research Report:A direct electrochemical Li recovery from spent Li-ion battery cathode for high-purity lithium hydroxide feedstock

Related Links

Rice University

Powering The World in the 21st Century at Energy-Daily.com