by Riko Seibo

Tokyo, Japan (SPX) Nov 18, 2025

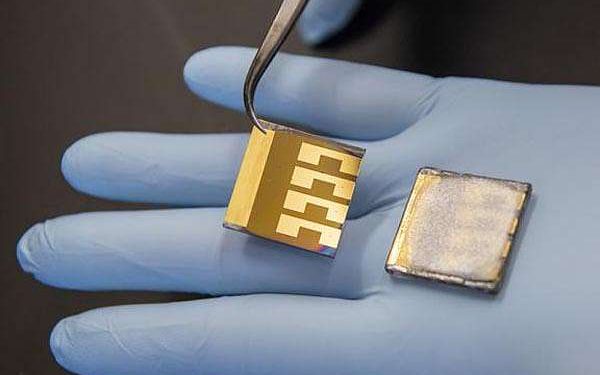

Researchers at Zhejiang University have mapped critical parameters governing crystallization in blade-coated perovskite films, clarifying pathways to manufacture high-efficiency solar cells and optoelectronics at commercial scale. The review addresses barriers posed by uneven crystallization, defects, and instability that emerge when perovskite deposition scales beyond laboratory dimensions.

Blade-coating combines simplicity with continuous manufacturing capability and efficient material use, positioning it as a front-runner for mass production. However, the method introduces variability in film thickness, crystallinity, and defect concentration. Complex nucleation and growth dynamics during coating produce inconsistencies that lower device efficiency and compromise long-term stability.

The team examined how solution chemistry, coating dynamics, environmental conditions, and post-treatments shape crystal nucleation, grain evolution, and defect distribution. Their findings integrate recent advances into a systematic framework for optimizing film formation in reproducible, scalable processes.

Solvent polarity and evaporation rate determine supersaturation and nucleation timing. Mixed solvent systems balance solubility against controlled crystal growth. Solution concentration and viscosity regulate film thickness and uniformity. High concentration slows evaporation and encourages defects, while low concentration restricts grain expansion.

Additives such as ammonium salts, surfactants, and coordination agents adjust nucleation density, passivate surfaces, and enhance interface quality. These chemicals improve grain ordering and stability. Coating parameters, particularly blade speed, control whether deposition operates in evaporation-dominated or Landau-Levich regimes, directly affecting crystal domain formation.

Substrate wettability manages liquid spreading and prevents dewetting. Gas-quenching accelerates solvent removal, triggering uniform crystallization. Ambient humidity and oxygen exposure modify reaction pathways, influencing phase purity and film stability.

“The performance and stability of perovskite devices depend heavily on how the film crystallizes during deposition,” the authors stated. “Understanding the interplay between solution chemistry, coating process, and environment allows us to systematically tune nucleation and grain growth. This is essential for producing uniform, defect-minimized films, particularly when scaling up from lab cells to large-area photovoltaic modules.”

The framework extends beyond solar cells to perovskite light-emitting diodes, photodetectors, and tandem configurations where film quality drives device output. Future developments may incorporate automated coating with real-time crystallization monitoring, alternative solvent chemistries with reduced environmental impact, and advanced passivation strategies.

These advances could accelerate commercial deployment of perovskite technologies in clean energy generation and optoelectronic devices. Coordinated control of chemical composition, fluid dynamics, and atmospheric conditions during drying emerges as the foundation for producing uniform, dense films with minimal defects across large areas.

Research Report: Key factors influencing perovskite film crystallization in blade-coating processes

Related Links

Zhejiang University

All About Solar Energy at SolarDaily.com